The perils of polystyrene and how custom fitted cardboard protective packaging can help you avoid it

When you’re thinking about packaging, you’re thinking about how to best cushion and protect your product to ensure it gets from point A to point B in perfect condition. Traditionally, cardboard is used for the outer part of product packaging in combination with materials like polystyrene or plastic on the inside.

The bad news is that polystyrene is terrible for the planet. And the good news? With a dash of custom engineering and a pinch of precision designed cardboard protective inserts, you don’t need polystyrene for your packaging! Here’s why it’s time to ditch polystyrene for good.

1. Polystyrene is a huge problem, literally.

About 45,000 tonnes of polystyrene are produced in Australia each year. That’s not to mention the huge amount coming into Australia from oversees in the form of packaging. On a global scale, many millions of tonnes of polystyrene are produced each year with a very low rate of re-use.

2. Polystyrene doesn’t get recycled.

You can’t recycle polystyrene in your normal home recycling bin. While it is possible to haul it to a recycling station, most people are likely to pop it into their rubbish bin instead, where it takes up space before heading swiftly to landfill.

Even worse, some types of polystyrene can’t be recycled at all. According to the Victorian Government Metropolitan Waste and Resource Recovery Group, about 40% of polystyrene in our state is of a non-recyclable variety and only 27% of all polystyrene in the state ends up being recycled.

3. Polystyrene takes many years to break down.

Discarded polystyrene can easily end up in our oceans. Scientists are still unsure exactly how long polystyrene takes to break down. It could be many hundreds of years and some scientists believe it never fully disappears. Instead, these scientists think polystyrene fractures into tinier and tinier pieces which marine life mistake for food.

4. Polystyrene is a hazardous substance.

Burning polystyrene releases dangerous carbon monoxide and other noxious emissions which are detrimental to our health. Styrene, the plastic used to make polystyrene, was identified as a possible carcinogen by the United States National Research Council.

5. With PPI, you don’t need polystyrene for your packaging!

Now that your eyes are open to the perils of polystyrene, you’re probably anxious to find an alternative packaging solution.

Lucky for you, at Production Packaging Innovations our in-house designers and engineers can create your perfect protective packaging solution without the need for polystyrene or plastic!

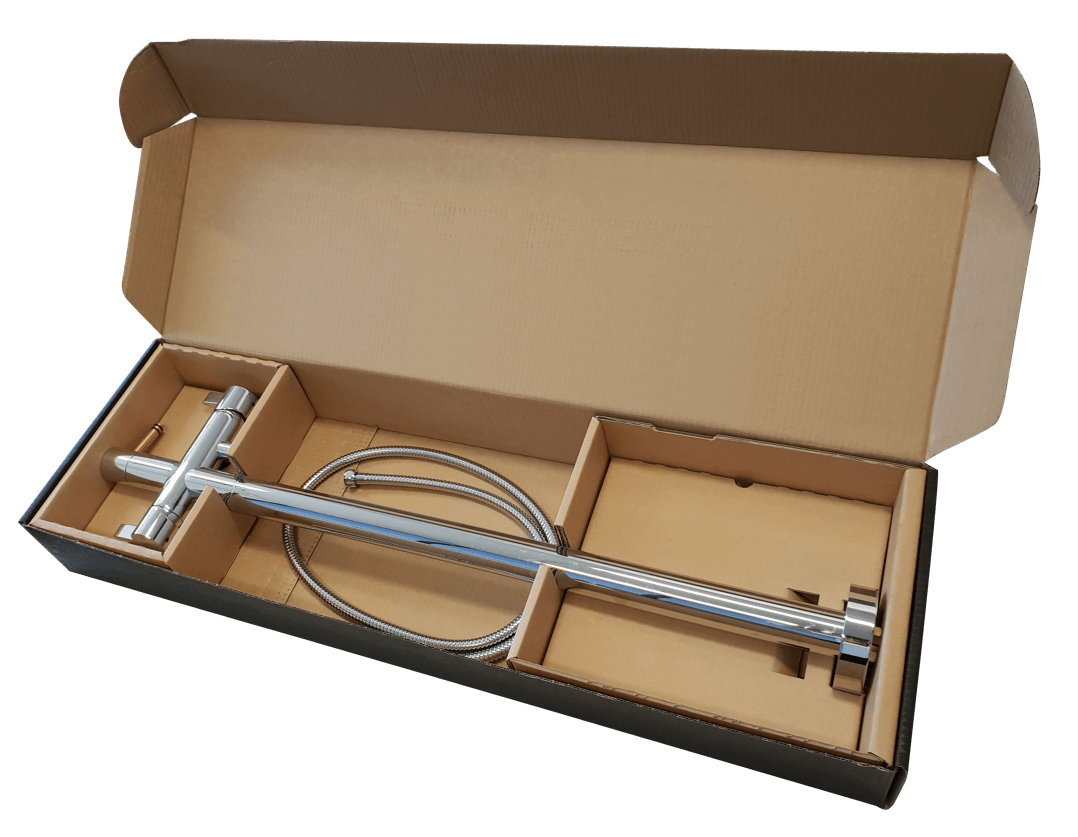

PPI utilises strategic engineering to create supportive carboard inserts and protective crumple zones to shield your product during transit. By combining cutting edge design practices with an attentive team creating customised solutions, we produce solutions that are both effective and sustainable. Who needs polystyrene when you have superior packaging expertise?

At PPI, our in-house team of packaging designers and engineers will work with you to understand your packaging needs. We offer custom solutions that are economical, protective and environmentally friendly.

Connect with us or call us now on 1800 25 8000 to book your FREE initial packaging consultation in Melbourne. We’ll work to ensure your packaging requirements are met, if not exceeded.

Recent case studies

Article

Getting Creative: Tips for Designing Bespoke Packaging

The packaging industry is consistently evolving, whether in terms of technology and design abilities or the growing need for creative packaging that d...

More

Article

How to Make Your Packaging Both Sustainable and Sturdy

In the wake of informed consumerism, customers have become highly conscious of only engaging with brands and businesses that align with their values. ...

More

Article

5 Reasons Why Bespoke Product Packaging is Important

In the era where consumers are increasingly transitioning to online shopping, product packaging and the unboxing experience it creates for a customer ...

More