Cracked Boxes, Damp Deliveries & Winter Packaging Woes (And How to Fix Them)

1. Is Your Packaging Ready for Winter?

Imagine a customer’s long-awaited order finally arrives. They open the door to a soggy box sitting on their doorstep. Inside? A cold, damp product that’s clearly taken a hit during transit. Not quite the unboxing experience you had in mind, right?

Winter might bring cosy vibes, but it’s not so kind to packaging. Rain, condensation and temperature drops can do more than give the shivers. They can wreak havoc on boxes, glue and product integrity. So the big question is: is your packaging winter-ready?

At PPI, we’ve seen it all, and we’re here to help you avoid the seasonal cold that can damage your product and your reputation.

2. The Cold, Hard Truth: How Winter Impacts Packaging

Cold weather throws a curveball at even the toughest packaging. Here’s how:

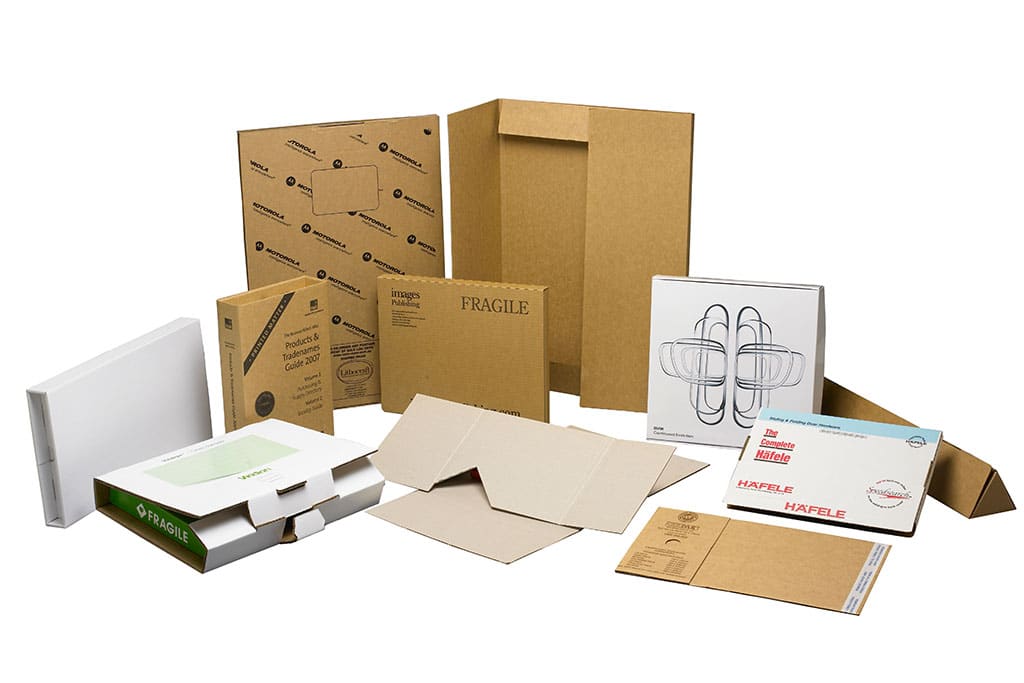

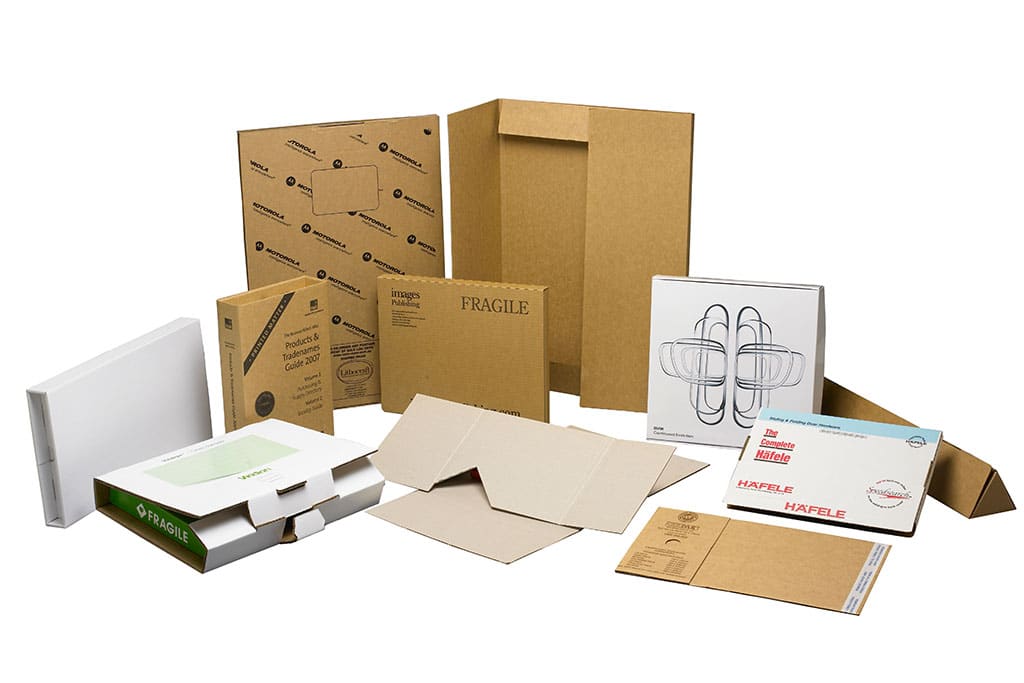

- Cardboard becomes fragile: Cold temps make cardboard more brittle, meaning it’s more prone to cracking, warping or tearing in transit.

- Glue can stop sticking: Adhesives are sensitive to temperature changes. In the cold, they can lose tackiness, which leads to failed seals and open boxes.

- Condensation causes chaos: Cold air outside and warm air inside can create condensation inside your package, leading to water damage, mould or ruined products.

If your packaging isn’t designed for cold-weather resilience, it could be the weak link in your supply chain.

3. The Top Winter Packaging Pitfalls (and How to Avoid Them)

Let’s get into the details of what can go wrong and how to stop it in its tracks.

Packaging Tearing During Transit

Cold makes cardboard rigid, so it loses its natural flexibility. When that happens, bumps and knocks in the delivery truck can easily cause cracks or full-on splits.

Fix it: Use reinforced cardboard or switch to a double-wall board for added strength. Our team at PPI can help you choose the right grade for the job.

Items Arriving Damp or Damaged

Condensation or wet weather can seep into packaging, especially if there are any weak points in the structure. Moisture damage can lead to product returns, health risks (in food) or ruined electronics.

Fix it: Consider water-resistant coatings, internal liners or switching to packaging designs that are less prone to moisture intrusion.

Boxes Not Sealing Properly

Colder temps affect glue bonding and sealing equipment. If glue doesn’t cure correctly, boxes might pop open during handling.

Fix it: Use adhesives tested for low-temperature performance or upgrade to sealing systems designed for winter use.

4. PPI’s Top Winter Packaging Recommendations

Here’s what we recommend to bulletproof your packaging for the colder months:

- Moisture-resistant coatings: Whether it’s rain or fridge humidity, protective coatings can keep the contents dry and pristine.

- Reinforced corners and seams: Structural weak points are more likely to fail in the cold. Reinforcements help boxes hold their shape.

- Crash lock boxes: These are ideal for in winter. They are strong, secure, and easy to assemble without relying on cold-sensitive adhesives.

- Cold-weather glue options: Not all adhesives do well in the cold. We’ll help you find one that sets and sticks, even in low temps.

We don’t do cookie-cutter packaging. We match the materials and structure to your unique product, process, and climate needs.

5. Product Feature Spotlight: How Our Tech Makes a Difference

Our packaging machinery is built for performance and that includes winter resilience. Here’s how some of our key equipment helps:

Crash Locking Gluers

Perfect for high-speed, low-fuss assembly. Crash lock designs are less reliant on glue, which makes them ideal when adhesive performance might be compromised.

Peel & Seal Glue Applicator

A game-changer for cold-room or fridge-packaged goods. The peel & seal system gives a reliable, tamper-evident closure. No matter the temperature.

Litho-Sheet Laminator

Ideal for premium packaging that requires a weatherproof finish. Laminated surfaces resist moisture, boost strength and hold up beautifully in winter conditions.

By using this technology in-house, we ensure that every product we supply can withstand the elements without compromising on either its appearance or functionality.

6. Industries That Need Winter-Ready Packaging the Most

While every business can benefit from stronger packaging, some industries are hit harder during winter months:

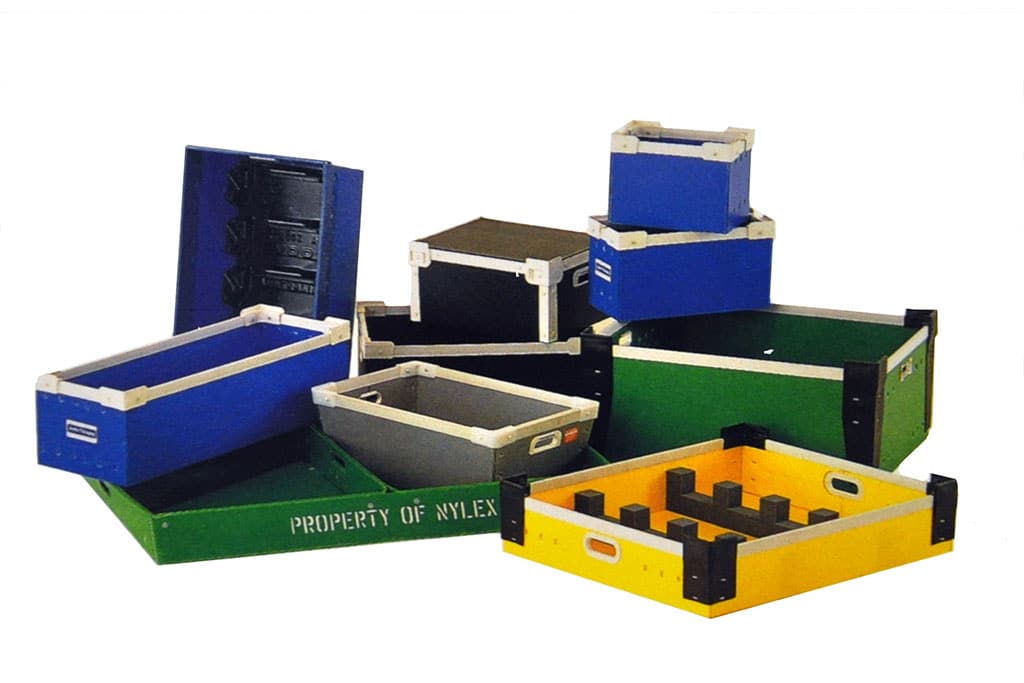

- eCommerce: Parcel volumes spike and long-distance shipping increases exposure to the elements.

- Food & Beverage: Chilled and frozen products need packaging that prevents moisture intrusion and temperature swings.

- Pharmaceuticals: Medicines and health products often have strict storage conditions that require them to remain dry and stable in order to maintain their effectiveness

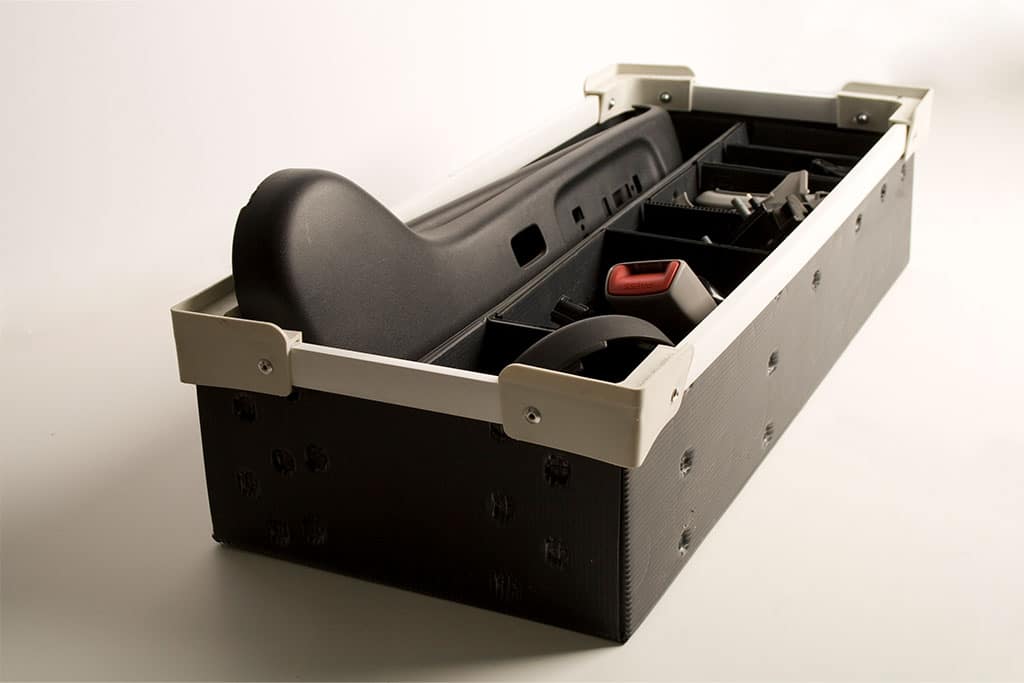

- Electronics: Sensitive components can be easily damaged by condensation or static caused by fluctuating temperatures.

- Cold Storage & Logistics: Even a short transfer between cold trucks and facilities can stress poorly sealed packaging.

If your industry relies on product integrity during transport, winter packaging prep should be part of your seasonal checklist.

7. Bonus Tips for Cold-Weather Shipping

Aside from your packaging materials, a few best practices go a long way:

- Think double wall: Single wall might do the job in summer, but for winter shipping, double wall board gives the edge in strength and durability.

- Pack tightly: Loose items shift more during transit, increasing the risk of box damage. Fill voids with inserts or custom-fit dividers.

- Use inserts and liners: Not only do they stop movement, but they can also add a layer of insulation and moisture protection.

8. Sustainable Winter Packaging: Can You Be Eco-Friendly & Weather-Resilient?

Yes, you absolutely can. Cold-weather protection doesn’t have to come at the cost of sustainability.

At PPI, we work with materials that are both durable and planet-conscious. Some of our favourites include:

- Water-based barrier coatings that offer protection without plastic films

- Reinforced FSC-certified board made from responsibly sourced fibres

- Fully recyclable liners and inserts that hold up to condensation and movement

Packaging can be both tough and thoughtful. If your brand values sustainability, we’ll help you deliver on that promise even in the middle of winter.

9. Aesthetic & Marketing Considerations: The Seasonal Appeal

Winter packaging is also a chance to connect with your customers on a more emotional level.

- Seasonal Design Cues: Winter-themed packaging often leans into icy blues, deep greens, warm reds or gold foils to evoke feelings of warmth, comfort and celebration.

- Textures & Finishes: Soft-touch coatings or matte finishes make unboxing feel cosy and premium, perfect for giftable products.

- Winter Graphics & Patterns: Snowflakes, pine trees or subtle winter-themed illustrations can elevate brand appeal and even encourage repeat purchases during the colder months.

At PPI, we help brands combine function and flair. Winter packaging can (and should) look as good as it performs.

10. How to Know If You Have a Winter Packaging Problem

Not sure if the cold is hurting your packaging? Look for these red flags:

- More customer complaints about damage during colder months

- Spikes in return rates between June and August

- Visible warping, cracking or box collapse in your warehouse

- Glue seals or tapes coming loose after storage or delivery

- Delays or bottlenecks in packaging lines due to temperature-sensitive adhesives

If any of this sounds familiar, it’s worth doing a winter packaging health check. Our experts can help you review your setup and find quick wins to improve resilience.

11. Pack Smart This Season

Cold weather doesn’t have to equal chaos. With the right packaging design, materials and technology in your corner, your products can arrive looking just as good as when they left.

At PPI, we love solving tricky packaging challenges and winter is no exception. If you’ve been seeing more damage, delays or disappointed customers in the colder months, it’s time to winter-proof your packaging.

Your product deserves to shine even when the weather doesn’t.

Contact us on 1800 25 8000 to find out how we can help you this winter.

Recent case studies

Article

The Complete Guide to Retainer Bulkheads for Safe and Efficient Bulk Export

Exporting bulk commodities such as grains, minerals, or industrial materials comes with unique challenges. Ensuring cargo remains secure during transp...

More

Article

Cracked Boxes, Damp Deliveries & Winter Packaging Woes (And How to Fix Them)

1. Is Your Packaging Ready for Winter? Imagine a customer’s long-awaited order finally arrives. They open the door to a soggy box sitting on their d...

More

Article

How Peal and Seal Packaging Can Streamline Your E-Commerce Operations

Introduction Packaging plays a vital role in ensuring smooth operations and a positive customer experience. As businesses scale, the pressure to strea...

More